CNC Watch & Jewelery DE Micro

THE HIGH-END SOLUTION for the highest demands

In the field of PREMIUM machines for PREMIUM requirements, this has become

machine system Watch & Jewelery DE Micro developed.

The systems are equipped with the highest quality industrial milling machine technology. The machine concept impresses above all with its precise, vibration-free and dynamic movement sequences in the demanding

and complex metalworking. All other relevant materials are

also be milled in high quality on this machine system or

to grind.

Especially for the creation of small parts from the areas:

Jewellery, watch parts and cases, medical technology, micro-processing, mold and prototype construction, and much more.

The Watch & Jewelery DE Micro includes a fully integrated automatic 15-position tool changer. As a result, the machine system can be operated at full capacity around the clock without supervision, with the same high level of precision.

the Watch & Jewelery DE Micro is a compact solution for machining workpieces up to 100x100x100 mm. It enables numerous materials such as titanium, steel, CoCr, ceramics, sapphire, zirconium or aluminum to be machined precisely.

Particularly noteworthy is the arrangement of the Y-axis, which ensures high stability and enormous vibration damping due to its installation position.

Almost all positions on the workpiece can be reached without reclamping. The selection of workpiece clamping devices and holders in connection with the zero-point clamping system makes the machine a versatile machining center. Their design enables wet/dry machining without time-consuming conversion.

The zero-point clamping system serves as an interface and ensures the exact and repeatable positioning of the workpiece.

The system can be integrated into network-controlled automated production processes using software interfaces.

The maintenance-friendly design and the durable direct spindle drives save service costs and time and offer a process-reliable machining system. During construction, care was taken to ensure that all elements are easily accessible and yet protected from external influences in order to guarantee a long service life. The mature system offers numerous options for expansion.

Thanks to the solid construction and the high quality of the components used, the machine guarantees reliable precision.

With the control integrated in the housing and the high-quality servo drives, excellent surface qualities are achieved on all materials.

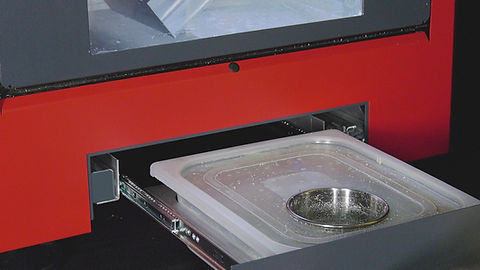

The practical coolant tank has a capacity of five litres.

For cleaning and filling, it can be easily pulled out and removed via a drawer underneath the machine.

The multi-stage filter system prepares the cooling lubricant for the system circuit and reliably retains chips and particles. The filter system can be easily removed and cleaned.

The machine can be used flexibly for a wide variety of materials. Metals and plastics can be processed wet and dry without retooling. The zero-point clamping system facilitates the handling of the workpieces

OPTIONS

-

machine base

-

automatic assembly system

-

various clamping devices

-

Liquid cooling for milling spindle

-

Extension for robot automation available (automatic exchange of holders)

Besonderheiten

-

5 Achsen Simultan CNC-Maschine ✓

-

Werkstück-Nullpunktspannsystem ✓

-

Integrierte Steuerung mit Touchscreen

wet milling

dry milling

5-Axis simultaneous

15 cutters automatic change

Temperature compensation

handling by touchscreen

ceramic blanks

different blanks

-28° / +100°

air cooling

0,5 μm

The powerful power pack is small, but can also process steel as well as aluminum - reliably and vibration-free.

The zero-point clamping system serves as an interface and ensures the exact and repeatable positioning of the workpiece. The system can be integrated into network-controlled automated production processes using software interfaces. The maintenance-friendly design and the durable direct spindle drives save service costs and time and offer a process-reliable machining system.

Thanks to the solid construction and the high quality of the components used, the machine enables high precision. With the control integrated in the housing and the high-quality servo drives, excellent surface qualities are achieved on all materials.

The machine can be used flexibly for a wide variety of materials. Metals and plastics can be processed wet and dry without retooling. The zero-point clamping system facilitates the handling of the workpieces

Millable materials

The practical coolant tank has a capacity of five litres. For cleaning and filling, it can be easily pulled out and removed via a drawer underneath the machine. The multi-stage filter system prepares the cooling lubricant for the system circuit and reliably retains chips and particles. The filter system can be easily removed and cleaned

Wet machining

Coolant is filtered and recirculated

Dry

Connection of a vacuum cleaner possible, suction nozzle available

sub table

stable aluminum / steel construction

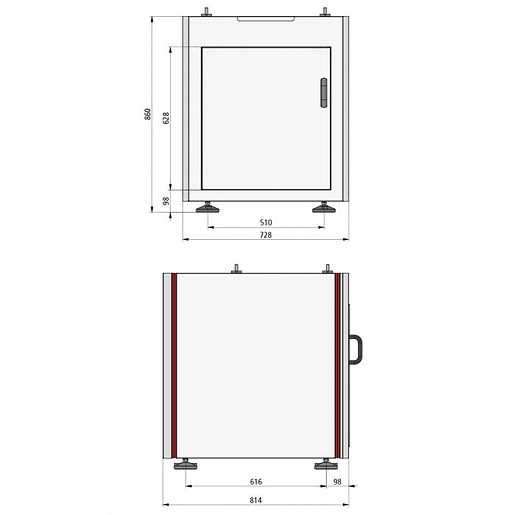

Dimensions [WxDxH]: 728 x 680 x 814 mm

Storage space for suction and cooling lubricant system

Storage volume: ≈ 0.25 m³

integrated leveling elements

When milling dry (e.g. wood), a suction unit can be connected to suck off the dust that has formed

CNC Watch & Jewelery DE Micro Premium

CNC Watch & Jewelery DE Micro Premium

Jewelery iMG 1010: 5-axis simultaneous

8. April 2022

iMG1010 - 5-Achs CNC-Fräsmaschine | isel Germany

Einfache Bedienung per Touchscreen